Nuclear low voltage switchgear plays a critical role in nuclear power plants by ensuring safe and reliable power distribution.

Our nuclear low voltage switchgear is designed to meet strict safety, seismic, and quality standards for critical applications.

The Role of Nuclear Low Voltage Switchgear in Power Plants

Nuclear low voltage switchgear plays a critical role in controlling and protecting motors, pumps, ventilation systems, lighting, and heating loads. It serves as the backbone of auxiliary power systems in nuclear facilities.

Due to the high-risk operating environment, safety and reliability standards for nuclear switchgear are significantly stricter than conventional industrial applications.

Compliance with Strict Nuclear Quality and Safety Standards

All nuclear low voltage switchgear must comply with national and international nuclear regulations and complete comprehensive qualification procedures.

Key requirements include:

Dedicated technical specifications for Q2 and Q3 equipment

Seismic, aging, and failure testing for nuclear island equipment

Safety interlocking, anti-misoperation, and redundancy design

These measures ensure long-term stable operation under extreme conditions.

High-Reliability Components and Lifecycle Monitoring

Core components must meet strict mechanical and electrical endurance standards.

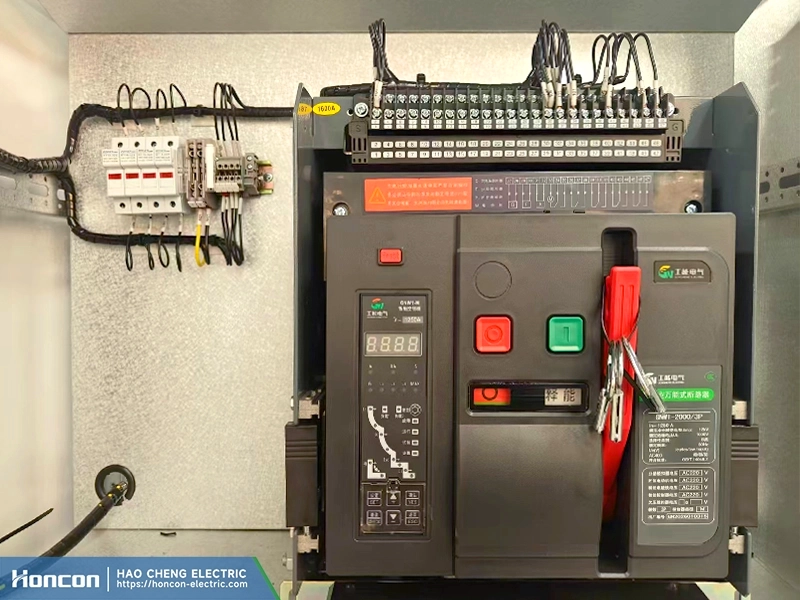

Intelligent Monitoring Functions

Important circuits are equipped with:

Operating time counters

Breaker opening and closing counters

Real-time status monitoring

This enables full lifecycle traceability and predictive maintenance.

Emergency and Normal Power Distribution Systems

Nuclear low voltage switchgear is mainly divided into two categories:

EE Emergency Switchboards

1E K3 safety classification

Q1 quality level

Class 1 seismic resistance

Designed for emergency power supply systems.

ER Normal Power Switchboards

Q3 quality level

NO seismic class

Suitable for normal operation systems

Both systems form a complete nuclear power distribution network.

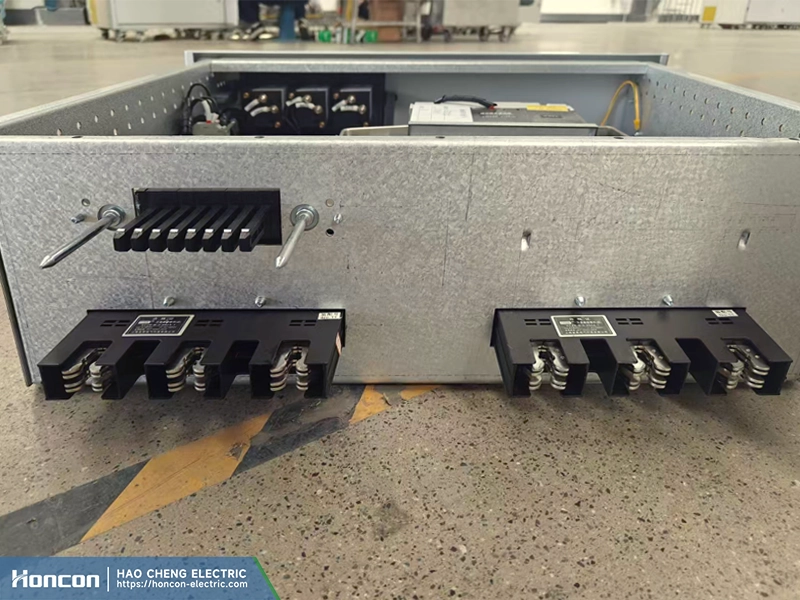

Structural Design for Harsh Nuclear Environments

Nuclear operating environments require advanced structural and manufacturing solutions.

Key design features include:

Standardized installation methods

Reinforced cable entry systems

High insulation and heat resistance

Anti-corrosion surface treatment

Clear and durable product identification

These designs ensure long-term stability in high-temperature, high-humidity, and radiation environments.

Customized Nuclear Switchgear Solutions and Full-Service Support

With years of experience in switchgear manufacturing, we integrate nuclear standards into every stage of product development.

Our solutions focus on:

Seismic-resistant cabinet structures

Advanced safety interlocking systems

Online circuit monitoring

Maintenance-friendly design

Customized power distribution solutions

We provide full lifecycle services from engineering design to commissioning and maintenance, supporting critical nuclear infrastructure worldwide.

To know more about us, kindly subscribe to our Youtube Channel: HONCON.