Green Switchgear Solutions Under New Productivity Standards

Green switchgear solutions play an essential role in supporting sustainable power systems under the new productivity model.

Modern electrical equipment manufacturers are shifting from extensive production to refined, low-carbon, and eco-friendly development, aiming to reduce resource consumption while ensuring product reliability.

By integrating green switchgear solutions into power infrastructure, enterprises can actively support carbon neutrality and long-term sustainability goals.

Key Challenges in Sustainable Switchgear Manufacturing

Despite rapid development, the industry still faces major environmental and cost challenges.

High Copper Consumption and Rising Costs

Pure copper offers excellent conductivity but is becoming increasingly expensive and scarce.

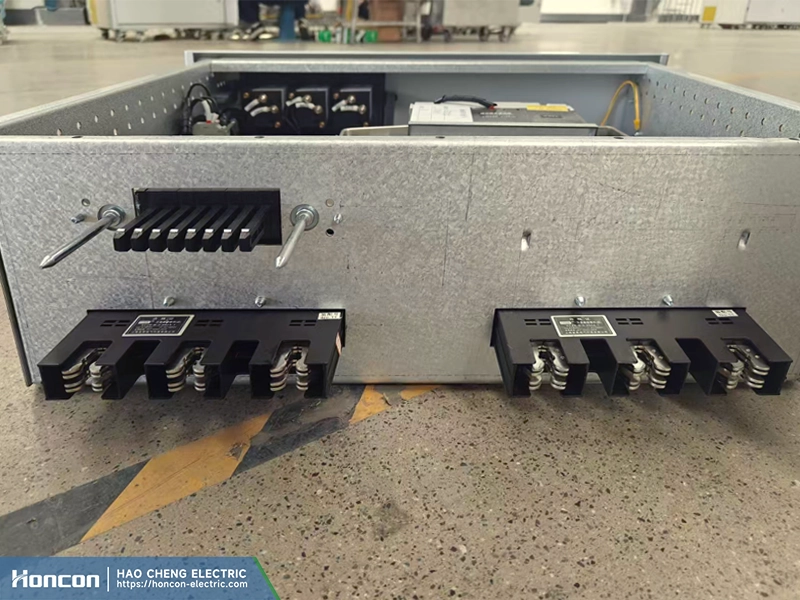

Optimized aluminum-based conductors provide effective alternatives:

D-type aluminum busbars with 1600 mm² cross-section can carry 1600A

Parallel installation reaches 2500A capacity

C-type busbars reduce copper usage and improve installation efficiency

These designs help reduce material costs while maintaining electrical performance.

Environmental Issues of Epoxy Resin Insulation

Epoxy resin is widely used in medium-voltage equipment due to mature manufacturing processes.

However, it presents several limitations:

Large insulation structures

Poor heat dissipation

Non-degradable materials

Limited recyclability

International markets increasingly adopt DMC insulation materials, which:

Require lower creepage distance

Meet ANSI standards

Offer better thermal performance

Support easy disassembly and recycling

Combined with through-core current transformers, DMC systems significantly simplify maintenance.

Material Selection for Green Switchgear Transformation

Sustainable transformation depends on precise material selection rather than excessive material usage.

High-efficiency and eco-friendly materials are key to:

Reducing operational costs

Improving system efficiency

Lowering carbon emissions

Supporting environmental compliance

Under the new productivity framework, green switchgear solutions become an essential foundation for modern power systems.

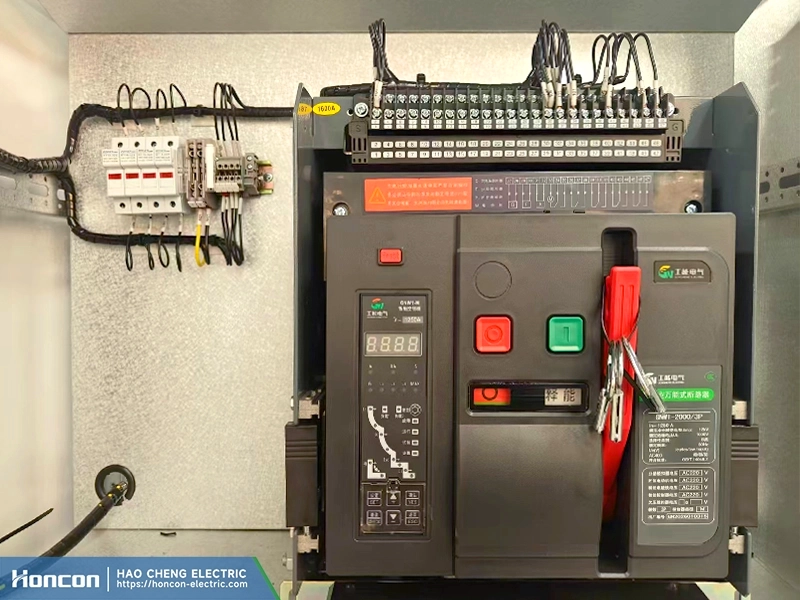

Our Sustainable Switchgear Solutions and Technical Advantages

With extensive experience in electrical equipment manufacturing, we integrate low-carbon principles throughout the product lifecycle.

Our solutions focus on:

D-type and C-type aluminum busbar systems

30%–50% copper consumption reduction

DMC insulation replacing epoxy resin

Modular and maintenance-friendly design

Customized project solutions

All products comply with international and domestic standards and are widely applied in renewable energy, grid modernization, and industrial power projects worldwide.

Driving Low-Carbon Power Infrastructure Development

By continuously improving green switchgear solutions, we help customers build safer, more efficient, and more sustainable power distribution systems.

Our mission is to support global energy transformation through innovative, reliable, and environmentally responsible electrical equipment.

If you are looking for reliable and sustainable power distribution solutions, our green switchgear systems provide a proven foundation for modern energy infrastructure.

We offer complete services from system design and manufacturing to installation and after-sales support.

Feel free to explore our customized switchgear solutions or contact our engineering team for professional consultation.

To know more about us, please kindly subscribe to our Youtube Channel: HONCON.

Frequently Asked Questions About Green Switchgear Solutions

What are green switchgear solutions?

Green switchgear solutions refer to environmentally friendly electrical equipment designed to reduce material consumption, improve energy efficiency, and support sustainable power systems.

How do green switchgear systems reduce copper usage?

By adopting optimized aluminum busbars and advanced conductor designs, green switchgear systems can reduce copper consumption by 30% to 50% without compromising performance.

Are DMC insulation materials better than epoxy resin?

Yes. DMC materials provide better heat dissipation, recyclability, and maintenance convenience, making them more suitable for modern eco-friendly switchgear systems.