Key Technical Challenges for FPSO Offshore Switchgear

FPSO offshore switchgear plays a critical role in providing reliable power on floating production, storage, and offloading (FPSO) units. These floating platforms integrate production, storage, and offloading functions, often operating in harsh marine environments. Globally, approximately 220 FPSOs are in operation, with deployments in Brazil, the UK North Sea, and other regions. The growth trend suggests 8–13 new units annually, increasing demand for high-reliability FPSO offshore switchgear solutions.

System-Level Requirements for FPSO Offshore Switchgear

FPSO platforms rely on modular prefabrication combined with hull integration. FPSO offshore switchgear must meet the following system-level requirements:

Align with topside process modules and hull electrical systems

Fit within prefabricated module dimensions and layout constraints

Comply with both marine and industrial electrical standards( see IEC 61439 Marine Switchgear Standards)

This requires switchgear to balance marine operational safety with industrial power distribution reliability.

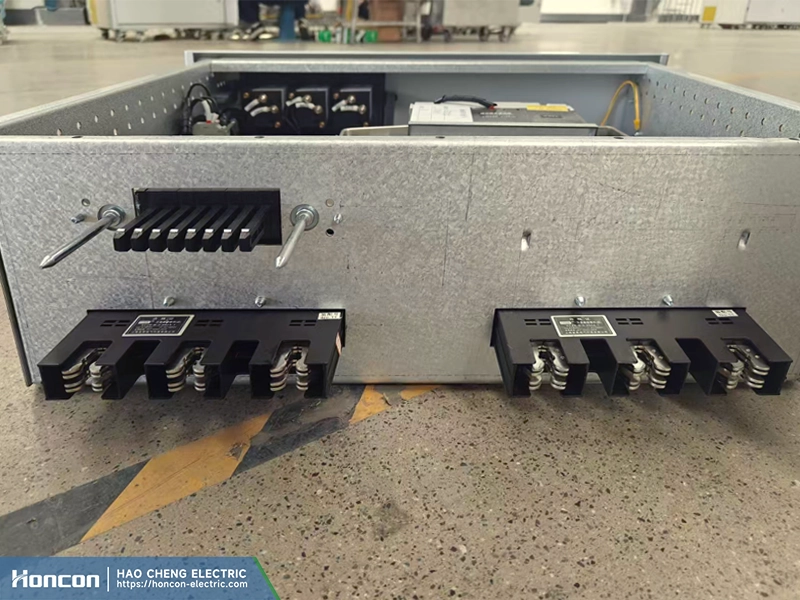

Extremely High Short-Circuit Currents and High Current Ratings

Short cable distances between generators and loads on FPSO units result in extremely high short-circuit currents. Typical requirements include:

Short-circuit currents up to 50kA–63kA

Main circuit rated currents between 3150A and 5000A

Consequently, FPSO offshore switchgear must integrate:

Circuit breakers rated for 40kA–63kA breaking capacity

Optional fast current-limiting devices for immediate fault current suppression

Fast current limiters reduce peak fault currents, protecting busbars, breakers, and connected equipment from mechanical and thermal stress.

High Power Supply Continuity and Long-Term Operation

FPSO platforms operate continuously, making power supply reliability critical. FPSO offshore switchgear design must focus on:

Long operational life

Maintenance-free or low-maintenance structures

Fast inspection and modular replacement capability

In addition, limited space on offshore platforms requires compact, high-density switchgear designs to minimize footprint while maintaining maximum safety.

Marine Protection and Type Test Compliance

Marine environments impose stringent protection and structural requirements:

Protection degree: IP42 or higher

Dedicated marine accessories such as handrails and door limiters

Compliance with marine type tests:

High ambient temperature (45°C)

Salt spray resistance

Vibration and shock testing

Platform tilt and roll simulations

These measures ensure FPSO offshore switchgear maintains electrical performance and structural stability in demanding conditions.

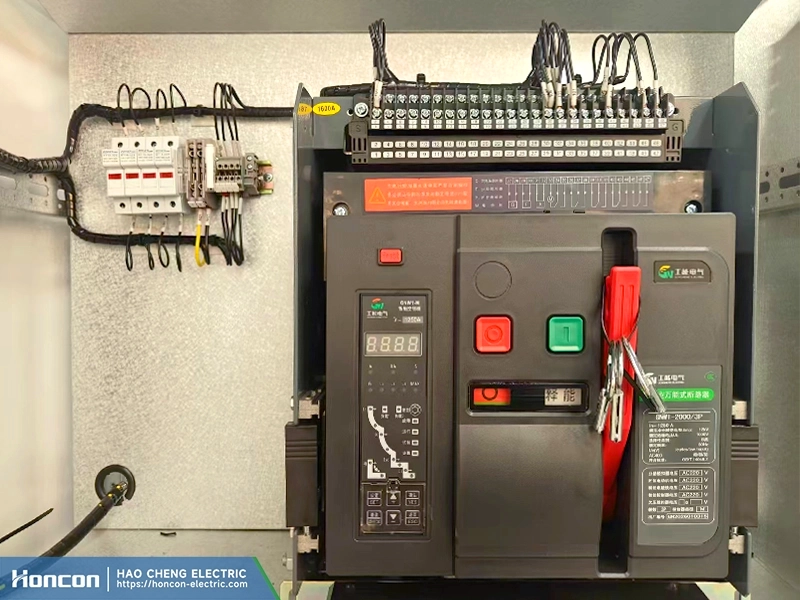

Internal Arc Classification and Arc Flash Protection

Personnel safety and equipment integrity require internal arc protection. Typical FPSO offshore switchgear standards include:

Internal Arc Classification: 50kA / 1s

Pressure relief channels designed for prefabricated module dimensions

Gas exhaust paths to prevent arc propagation

Arc flash protection systems use sensors to detect faults within milliseconds, rapidly tripping affected breakers and limiting fault spread, ensuring platform electrical safety.

Customized FPSO Offshore Switchgear Solutions

We provide customized FPSO offshore switchgear solutions that address:

High short-circuit current capacity

Large current busbar and breaker coordination

Compact, high-reliability structural optimization

Compliance with marine tests and IP requirements

Modular design for prefabricated installation

Supported by a professional R&D team and strict manufacturing quality control, our FPSO offshore switchgear meets international standards and delivers high reliability for global offshore oil & gas and industrial power distribution projects. Our solutions ensure continuous, safe, and long-term operation for energy-intensive marine applications.